Solar Panels in Series vs Parallel: Complete Wiring Diagram Guide

Series or parallel? It's the most common solar wiring question. Here's exactly when to use each configuration, with clear diagrams showing how to wire your panels correctly.

"Should I wire my solar panels in series or parallel?" It's the question every DIY solar installer asks, and the wrong answer can cost you efficiency, money, or both.

The short answer: Series wiring is better for most RV, boat, and off-grid installations. You get smaller wires, less power loss, and lower costs. Parallel only makes sense in specific situations like partial shading or when you're limited to 12V charge controllers.

Let's dig into why, with clear diagrams showing exactly how each configuration works.

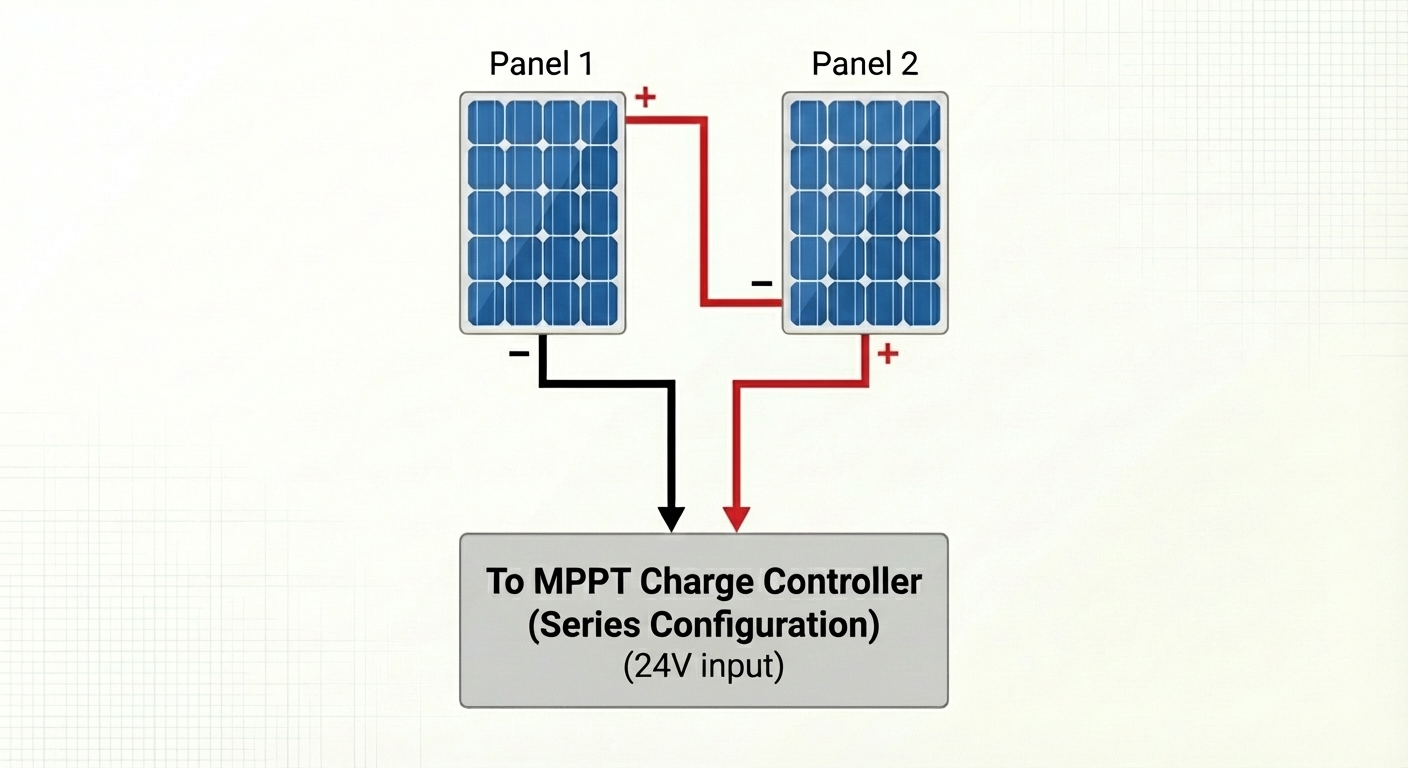

Solar Panels in Series: How It Works

When you wire solar panels in series, you connect the positive terminal of one panel to the negative terminal of the next. The voltages add together while current stays the same.

Example: Two 100W panels (18V, 5.5A each)

- Series voltage: 18V + 18V = 36V

- Series current: 5.5A (unchanged)

- Total power: 36V x 5.5A = 198W

Solar Panels in Series Diagram

The positive from Panel 1 connects to negative of Panel 2. Your final connections to the charge controller are the remaining positive (from Panel 2) and negative (from Panel 1).

Why Series Wiring Wins for Most Installations

Lower current = smaller wires

At the same power level, series wiring carries less current. Less current means you can use smaller, cheaper wire gauges.

| Configuration | Voltage | Current | Wire Gauge (20ft) |

|---|---|---|---|

| 400W Parallel (12V) | 18V | 22A | 6 AWG |

| 400W Series (48V) | 72V | 5.5A | 14 AWG |

That's a massive difference in copper costs and installation difficulty.

Less power loss

Power loss in wires is proportional to current squared. Higher voltage, lower current systems lose dramatically less power:

- Parallel 400W at 20ft: ~8% voltage drop with 10 AWG

- Series 400W at 20ft: ~1% voltage drop with 14 AWG

Better charge controller efficiency

MPPT charge controllers work by converting high-voltage solar input to the appropriate battery voltage. With series wiring, they have more headroom to find the optimal power point, especially in hot weather when panel voltage drops.

Reduced fire risk

Lower current means less heat generation at connections. High-current parallel systems stress every connector, junction, and wire termination.

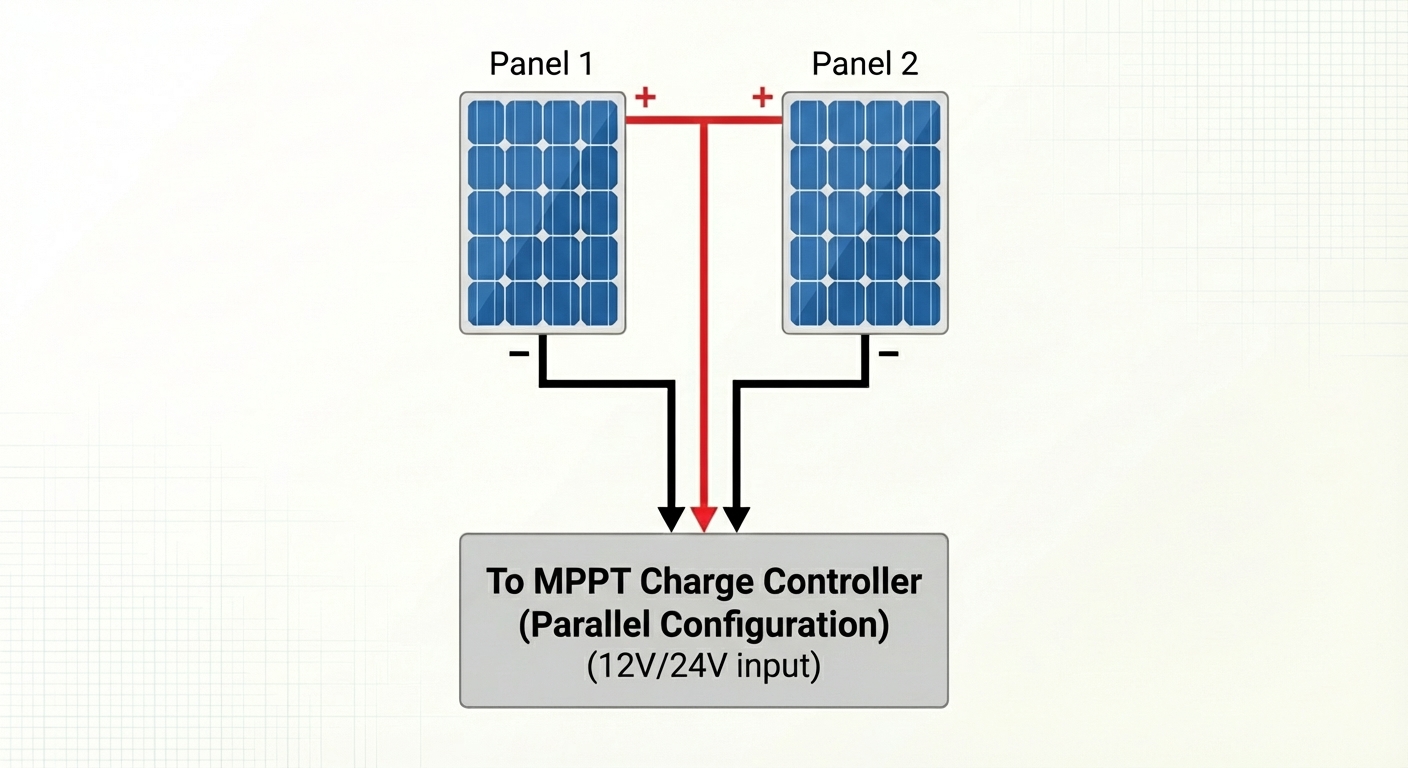

Solar Panels in Parallel: How It Works

Parallel wiring connects all positives together and all negatives together. Current adds while voltage stays the same.

Example: Two 100W panels (18V, 5.5A each)

- Parallel voltage: 18V (unchanged)

- Parallel current: 5.5A + 5.5A = 11A

- Total power: 18V x 11A = 198W

Solar Panels in Parallel Diagram

When Parallel Actually Makes Sense

Parallel wiring isn't always wrong - there are specific situations where it's the better choice:

Significant partial shading

In series, a shaded panel drags down the entire string. In parallel, shaded panels only affect themselves.

However: Most quality panels have bypass diodes that mitigate this. Series still works fine with occasional partial shading.

PWM charge controllers

PWM controllers need input voltage close to battery voltage. If you're stuck with a PWM controller, parallel might be your only option.

However: MPPT controllers are now affordable and 20-30% more efficient. Upgrading usually makes more sense than designing around PWM limitations.

Mixing different panels

Panels with different specifications work better in parallel since each operates independently.

However: Mixing panels is generally a bad idea. Better to sell the odd panel and standardize.

Very short wire runs

If your panels are right next to your charge controller (under 10 feet), the wire savings of series wiring are minimal.

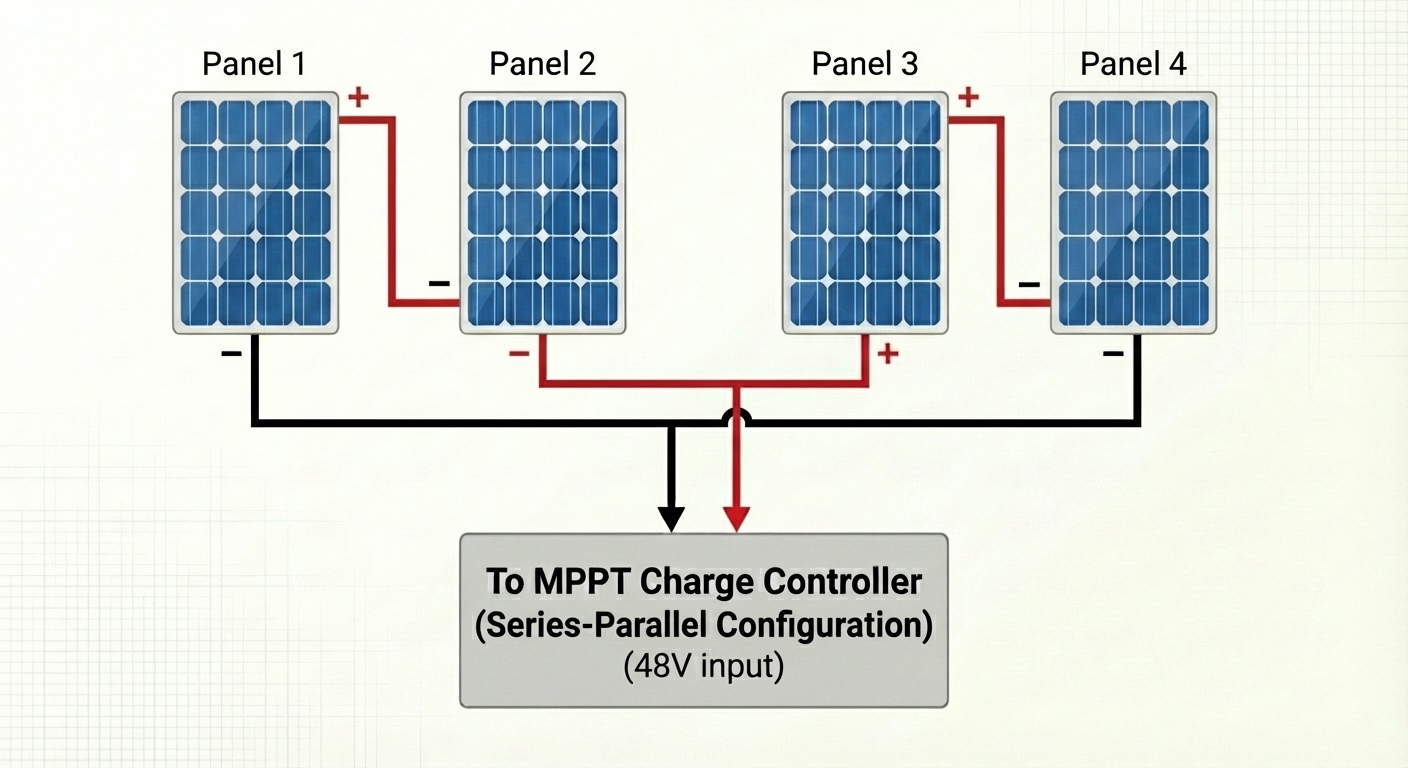

Series-Parallel Combinations

Large solar arrays often use both: panels wired in series to form "strings," then strings wired in parallel.

Series-Parallel Diagram (4 Panels)

String specs (2 panels each):

- String voltage: 36V

- String current: 5.5A

Combined array:

- Total voltage: 36V

- Total current: 11A

- Total power: ~400W

This gives you the high-voltage benefits of series wiring while scaling up power capacity.

Practical Solar Panel Wiring Guide

Step 1: Check Your Charge Controller

Your charge controller's maximum input voltage determines your options:

| Controller Type | Max Input | Series Capability |

|---|---|---|

| Basic PWM | ~30V | 1-2 panels |

| Entry MPPT | 75-100V | 3-5 panels |

| Mid-range MPPT | 100-150V | 6-8 panels |

| High-end MPPT | 150-250V | 10+ panels |

Safety margin: Keep your maximum series voltage at least 10% below controller limits. Panel voltage rises in cold weather.

Step 2: Calculate Your String Size

Formula: Number of panels = Controller max voltage / Panel Voc / 1.1 (safety factor)

Example with 100V controller and 22V Voc panels: 100 / 22 / 1.1 = 4.1 panels maximum per string

Step 3: Size Your Wiring

Even with series wiring's lower current, proper wire sizing matters:

| String Current | Max Distance | Minimum Gauge |

|---|---|---|

| 5-6A | 30 ft | 14 AWG |

| 8-10A | 30 ft | 12 AWG |

| 15-20A | 30 ft | 10 AWG |

Use proper wire sizing calculations for your specific installation.

VoltPlan and Series Solar Wiring

VoltPlan diagrams default to series wiring because it's the right choice for the vast majority of installations. Our templates show proper series connections with appropriate wire sizing for your panel configuration.

When you're ready to design your solar system:

- Start with our off-grid solar template

- Add your specific panels and adjust quantities

- VoltPlan calculates wire sizes automatically

- Export your complete wiring diagram

The Bottom Line on Series vs Parallel

Use series wiring when:

- You have an MPPT charge controller (you should)

- Wire runs are more than a few feet

- You want to minimize costs and power loss

- Your panels are identical

Consider parallel wiring when:

- You're stuck with a PWM controller

- You have significant, consistent shading issues

- You must mix different panel types

- Wire runs are extremely short

For 90%+ of RV, boat, and off-grid installations, series wiring is the clear winner. Don't let outdated advice push you toward parallel - modern MPPT controllers make series the obvious choice.

Start designing your solar panel system with VoltPlan's free diagram creator. We'll help you get the wiring right the first time.

Ready to Design Your Electrical System?

Use VoltPlan's free electrical system designer to turn these concepts into reality.

Start Your Project